There is a new feature introduced from Maximo 7.5 which allows users to schedule payments. You can use the Contract Line Items tab in the Contracts application to create a schedule of payments for the contract line items. I am going to present some scenarios where this feature can be useful and how the invoice is created for the same.

Points of Consideration and Scenarios for Payment Schedule functionality:

- Payment Schedule can be created for each contract line.

- Before you can create a payment schedule, you must select the Payment Schedule check box on the Properties tab.

- Out of the box payment schedule can be used to create Invoice on PO Approval and Receipt of Materials:

- Payment Percent should be selected such that line cost of each milestone do not exceed total line cost.

- For Example: A contract line has total line cost as 1000,

- Payment % for action POAPPR= 10, line cost=10% of 1000=100

- Payment % for action RECEIPT=90, line cost=90% of 1000=900

- Scenario 1: Contract Line with Qty=10, Unit Cost=100, Line Cost=1000,

- Payment Schedule 1: Action=POAPPR, Payment Percent=10, Line Cost=100

- Payment Schedule 2: Action=RECEIPT, Payment Percent=90,

Line Cost=900

- On PO approval, one invoice is created as: Invoice Qty=Ordered Qty=10, Unit Cost=10% of 100=10, Invoice Line Cost=100

- On partial receipt of 6 items, one invoice is created as: Invoice Qty=90% of Received Qty=90% of 6=5.4, Unit Cost=100, Invoice Line Cost=540

- On receipt of remaining 4 items, one invoice is created as: Invoice Qty=90% of Received Qty=90% of 4=3.6, Unit Cost=100, Invoice Line Cost=360

- Scenario 2: Contract Line with Qty=10, Unit Cost=50, Line Cost=500

- Payment Schedule 1: Action=RECEIPT, Payment Percent=100, Line Cost=500

- On Partial Receipt of 5 items, one invoice is created as: Invoice Qty=100% of Received Qty=100% of 5=5, Unit Cost=50, Invoice Line Cost=250

- On Partial receipt of 3 more items, one invoice is created as: Invoice Qty=100% of Received Qty=100% of 3=3, Unit Cost=50, Invoice Line Cost=150

- On receipt of remaining 2 items, one invoice is created as: Invoice Qty=100% of Received Qty=100% of 2=2, Unit Cost=50, Invoice Line Cost=100

- Scenario 3: Contract Line with Qty=10, Unit Cost=100, Line Cost=1000

- Payment Schedule 1: Action=RECEIPT, Payment Percent=20, Line Cost=200, Days Interval=7

- Payment Schedule 2: Action=RECEIPT, Payment Percent=80, Line Cost=800, Days Interval=7

- On partial receipt of 5 items, two invoices are created as:

- Invoice Date=7 days after receipt, Invoice qty=20% of Received Qty=20% of 5=1, Unit Cost=100, Invoice Line Cost=100

- Invoice Date=30 days after receipt, Invoice qty=80% of Received Qty=80% of 5=4, Unit Cost=100, Invoice Line Cost=400

- On partial receipt of 2 more items, two invoices are created as:

- Invoice Date=7 days after receipt, Invoice qty=20% of Received Qty=20% of 2=0.4, Unit Cost=100, Invoice Line Cost=40

- Invoice Date=30 days after receipt, Invoice qty=80% of Received Qty=80% of 2=1.6, Unit Cost=100, Invoice Line Cost=160

- On receipt of remaining 3 items, two invoices are created as:

- Invoice Date=7 days after receipt, Invoice qty=20% of Received Qty=20% of 3=0.6, Unit Cost=100, Invoice Line Cost=60

- Invoice Date=30 days after receipt, Invoice qty=80% of Received Qty=80% of 3=2.4, Unit Cost=100, Invoice Line Cost=240

Example for Scenario 1

- Created one Purchase Contract with one contract line with payment schedule as below:

- OrderQty=10, Unit Cost=100, Line Cost=1000

- Payment%=10, Action=POAPPR, Line Cost=100

- Payment%=90,

Action=RECEIPT, Line Cost=900

- PO created for the above contract and approved as below:

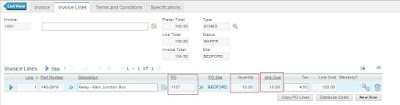

- On PO approval, an invoice is created as below with Pretax Total = 10% of 1000 = 100 USD:

- Receiving 6 items out of 10 ordered for Partial Receipt as below:

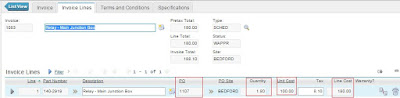

- One invoice is created for the above partial receipt as below:

- Receiving 2 more items as below:

- Invoice created for above receipt as below:

- Receiving remaining 2 items as below:

- Invoice Created for above receipt as below:

I hope this blog will help people in understanding how this feature works. Please feel free to share your comments.